Diesel engines are known for strength, reliability, and long service life. Many are built to run hundreds of thousands of miles or thousands of operating hours. What often gets overlooked, however, is how dependent that durability is on the fuel delivery system. Fuel injectors and injection pumps sit at the center of diesel engine operation, controlling how fuel enters the combustion chamber, how finely it is atomized, and when it is delivered.

When these components begin to wear, the engine rarely fails suddenly. Instead, performance changes gradually. These changes are easy to dismiss as normal aging or heavy use, but ignoring them can allow small fuel-system issues to develop into costly engine damage.

Knowing the warning signs helps diesel owners take action early and restore proper engine behavior.

Why Fuel Injectors and Injection Pumps Matter So Much

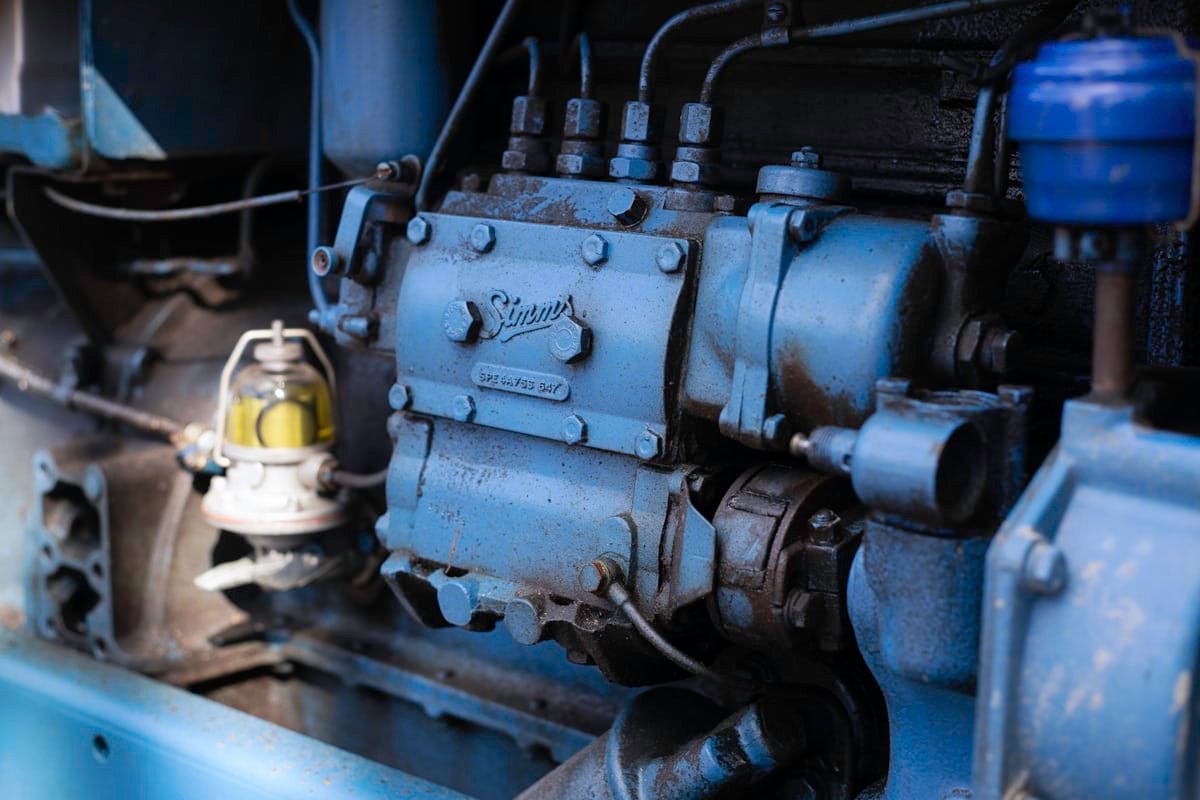

Diesel engines operate very differently from gasoline engines. Rather than relying on spark plugs, diesel engines ignite fuel using heat created by compressed air. This process requires extreme precision. Injectors must deliver fuel at high pressure in a controlled spray pattern, while the injection pump regulates fuel timing and volume to match engine speed and load.

When either component loses accuracy, combustion becomes uneven. Fuel may arrive too early, too late, or in the wrong quantity. Even slight deviations affect power output, emissions, fuel efficiency, and internal engine stress.

Hard Starting and Delayed Ignition

One of the earliest and most common warning signs of injector or pump wear is difficulty starting the engine. This may manifest as longer cranking times, especially during warm starts or after short shutdowns.

Worn injectors may leak fuel internally or fail to produce a clean spray, reducing ignition consistency. Injection pumps with internal wear may struggle to build pressure quickly. While the engine eventually starts, repeated cranking places additional strain on the starter, battery, and electrical system.

Rough Idle and Uneven Engine Operation

A healthy diesel engine should idle smoothly once it reaches operating temperature. Fuel delivery issues often manifest at idle because the engine is running at low speed with minimal margin for error.

Common idle-related symptoms include:

- Shaking or vibration felt through the steering wheel or cab

- RPM fluctuations or surging

- An uneven exhaust note

These issues typically worsen when the engine transitions from idle to light throttle or when accessories are engaged. Over time, rough idle conditions can lead to increased wear on engine mounts and driveline components.

Loss of Power Under Load

Fuel system problems become much more noticeable when the engine is under stress. If a diesel vehicle struggles during acceleration, towing, or hill climbs, fuel delivery may be the limiting factor.

Injection pumps lose efficiency as internal components wear, reducing their ability to maintain pressure during high demand. Injectors with worn or restricted nozzles cannot supply enough fuel volume. The result is reduced torque, slower throttle response, and an engine that feels strained even under moderate loads.

Excessive or Unusual Exhaust Smoke

Exhaust smoke changes are among the clearest indicators of combustion problems. When fuel delivery becomes inconsistent, smoke patterns often appear before more serious mechanical symptoms.

- Black smoke usually points to excess fuel that is not fully combusting

- White smoke often indicates delayed injection or poor atomization

- Gray smoke may suggest uneven combustion between cylinders

These smoke conditions not only reduce efficiency but also increase carbon buildup in the exhaust system and combustion chamber.

Increased Fuel Consumption Without Performance Gains

A failing injector or pump often causes the engine to burn more fuel without producing additional power. Leaking injectors, unstable spray patterns, or inconsistent pressure force the engine to compensate by increasing fuel delivery.

Drivers may notice declining fuel economy even though driving habits have not changed. Over time, this increased consumption raises operating costs and accelerates carbon buildup throughout the engine.

Abnormal Engine Noise and Combustion Knock

Diesel engines naturally produce more noise than gasoline engines, but changes in sound should not be ignored. Faulty injectors can cause sharp knocking, ticking, or metallic sounds, especially under load.

These noises occur when fuel is injected at the wrong moment or unevenly across cylinders. Improper combustion timing increases stress on pistons, bearings, and connecting rods. Continued operation under these conditions can significantly shorten engine life.

Check Engine Light and Fuel-Related Fault Codes

Modern diesel engines rely on sensors to monitor fuel pressure, injector balance, and combustion quality. When readings fall outside acceptable ranges, fault codes may be triggered.

While a single fault code does not necessarily indicate injector or pump failure, repeated fuel-related fault codes often indicate underlying mechanical wear rather than electronic issues.

Clearing codes without addressing the root cause usually results in the problem returning.

Fuel Contamination and Accelerated Component Wear

Fuel quality plays a major role in injector and pump lifespan. Water, dirt, and debris in diesel fuel cause internal scoring, corrosion, and seal damage.

Even with proper filtration, prolonged exposure to contaminated fuel shortens component life. Once internal wear begins, performance typically declines steadily rather than failing abruptly. This gradual decline is why fuel system problems are often underestimated.

Cold Start Issues and Seasonal Performance Changes

Fuel system wear often becomes more noticeable during cold weather. Injectors that struggle to atomize fuel or pumps that fail to maintain pressure can make cold starts difficult.

Engines may require extended cranking, produce white smoke at startup, or idle roughly until warm. These seasonal symptoms are often the first sign that fuel delivery components are approaching the end of their service life.

Uneven Cylinder Performance and Injector Balance Problems

Modern diesel engines rely on balanced fuel delivery across all cylinders. When one injector wears faster than others, cylinder balance is disrupted.

This imbalance may not cause immediate failure, but it leads to vibration, uneven power delivery, and increased stress on rotating components. Over time, the imbalance can affect crankshaft bearings and transmission components.

When Replacement Becomes the Practical Solution

While some injectors and pumps can be rebuilt, replacement often becomes the more reliable long-term option once wear reaches a certain point. Modern diesel fuel systems operate at extremely high pressures, leaving little tolerance for partially worn components.

Replacing worn injectors or pumps restores proper spray patterns, pressure stability, and timing accuracy. This allows the engine to return to smooth, predictable operation rather than compensating for inconsistent fuel delivery.

In many real-world cases, replacing worn components proves more reliable than repeated repairs. Diesel owners often explore professionally tested fuel injectors matched to engine specifications, such as those available from established suppliers like Goldfarb & Associates Inc., to restore consistent fuel delivery and stable engine operation.

Preventive Habits That Protect Fuel Systems

Although wear is inevitable, good maintenance habits can slow the process:

- Use clean, high-quality diesel fuel

- Replace fuel filters at recommended intervals

- Drain water separators regularly

- Address early performance changes promptly

Preventive care reduces downtime and helps avoid secondary engine damage.

Why Fuel System Problems Are Often Misdiagnosed

Because injector and pump wear develops gradually, symptoms are often attributed to turbochargers, sensors, or general engine aging. Replacing unrelated components may temporarily mask symptoms without resolving the underlying issue.

Understanding how fuel delivery affects combustion helps narrow the diagnosis and avoid unnecessary repairs.

A Practical Perspective on Fuel Injector and Pump Replacement

Fuel injectors and injection pumps influence nearly every aspect of diesel engine performance. When these components degrade, the effects are observed across start-up behavior, idle quality, power delivery, fuel economy, and emissions.

Replacing worn fuel system components restores balance to the combustion process instead of masking symptoms with temporary fixes or additives.

A Balanced Conclusion on Fuel System Health

Fuel delivery issues rarely announce themselves all at once. They reveal themselves through gradual changes in how a diesel engine starts, idles, and performs under load.

Recognizing these signs early allows diesel owners to replace injectors or pumps before wear spreads to other engine components. Maintaining a healthy fuel delivery system supports reliable operation, efficient fuel use, and long-term engine durability.